Splash Zone Crossing

Lifting through the splash zone is a key application area for Cranemaster. Hundreds of spool systems, mud mats, manifolds and suction anchors have successfully crossed the splash zone supported by a Cranemaster unit.

Operational Challenges

Operational challenges when performing a splash zone crossing includes:

- Limited operational weather window due to dynamic loads.

- Large forces on structures during crossing, especially complex structures and structures with large horizontal surfaces (e.g. manifolds).

- Crossing of structures with large variation between weight in water and air.

Cranemaster Benefits

The Cranemaster units provides significant benefits during a spash zone lift:

- Reduce dynamic force in payload and lifting points during splash zone crossing.

- Reduce dynamic load on the crane tip and the hoisting system.

- Reduce probability of slack wire during splash zone crossing.

- For challenging applications, Cranemaster Advanced Splash Zone Tension Mode (CAST) gives unsurpassed performance in terms of low DAF and the ability to avoid slack slings even for large objects and high waves.

Splash Zone Crossing With and Without Cranemaster

This Orcaflex simulation shows a splash zone crossing of a manifold structure. Applying a Cranemaster significantly reduces the forces in load and crane are . Furthermore, the stability increases and the DAF is reduced from around 5.0 to 1.1. The minimum tension in the crane wire is not acceptable without Cranemaster.

Engineering Services and Simulation of Splash Zone Crossing with OrcaFlex

Read more: Our Engineering Services

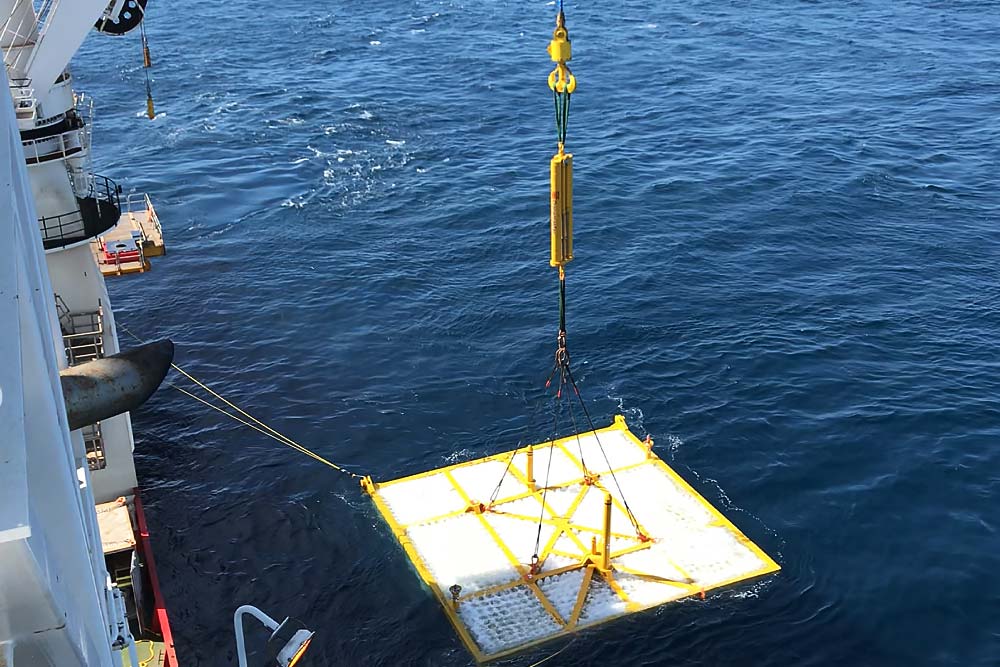

Cranemaster in Action Through the Splash Zone

Key considerations

Slamming forces, added mass and drag of the object can increase the forces transferred to the crane and the object by many times the weight of the object. Snap loads caused by wave or boom-tip motion may be very large. DNV´s Recommended Practice DNV-RP-H103 from April 2011, thoroughly describes the general principles and issues are.

With Cranemaster mounted, these forces are removed or reduced significantly. The main functionality of Cranemaster is to decouple the movement of the boom tip from the movement of the load. The Cranemaster spring force helps avoid slack wire during the splash zone transfer. While, excessive forces in crane or load due to wave and boom tip movements are removed by a combination of the spring and dampening forces of the Cranemaster unit.

Selection and Tuning

- The maximum stroke of Cranemaster should be longer than the boom tip movement.

- Cranemaster should have a spring response corresponding to the maximum allowable forces on load and crane.

- Cranemaster should have dampening forces tuned according to the expected boom-tip and characteristic vertical water particles accelerations.

- A slack wire may be acceptable because a Cranemaster unit picks up the snap load. However, load stability may be a concern and it should therefore generally be avoided.

- A full stroke is not acceptable since the Cranemaster unit then will give no protection. We recommend a safety margin of 5%-15% of maximum stroke.

Case Studies

Talk to us about your project

Skip to read more about splash zone crossing with Cranemaster