Control Systems

For demanding operations we offer several solutions for enhanced performance and control. All control systems are designed with maximum focus on safety, and depending on system, they offer sensor redundancy, manual override and fail-safe modes. The computer based systems are DNV GL technology certified.

Cranemaster Adaptive Control – Adaptive change of settings during lifting

Quick Lift – Avoid re-contact after lift off

For cranes with a slow lifting speed, there may be a risk of re-contact between the structure and the barge. Using on-board Nitrogen pressure, the Quick Lift functionality will lift the load by pulling in the piston and thereby avoiding re-contact.

Lock & Release

The radio-controlled locking system will reduce rigging height by locking the piston in zero-stroke during over-boarding, avoiding the static stroke in air. The system may also be used to lock the piston subsea if required based on depth or ROV control.

Weight & Temperature Correction

Correction in air and water for temperature variations and variations in load weight and buoyancy. Deviations from calculated loads weigh does not influence performance.

Depth Compensation

A common challenge when using Passive Heave Compensators in deep water, is the deep water pressure pushing the piston back in, resulting in reduced efficiency of the system.

With depth compensation, the efficiency of the Cranemaster is maintained during deep water operations by limiting the effect of water pressure on the stroking of the Cranemaster.

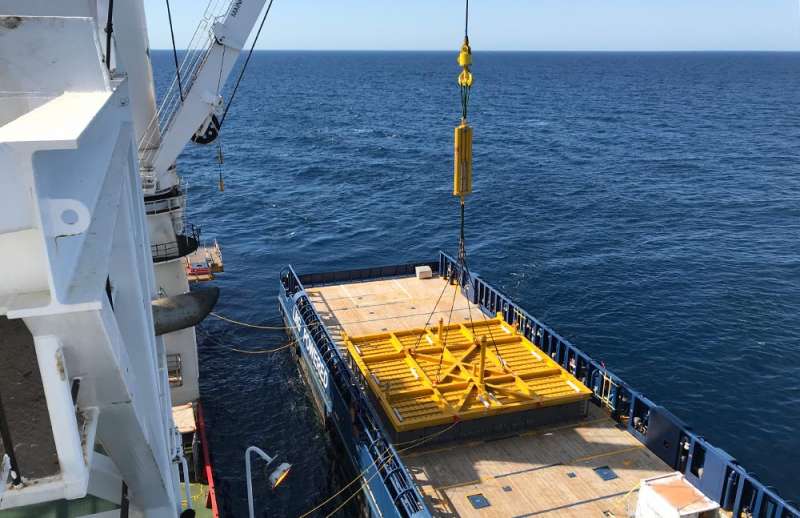

Advanced Splash Zone Tension mode (CAST)

The Cranemaster Advanced Splash Zone Tension mode (CAST) changes the spring characteristics continuously during the stroke cycle, providing an optimized stiffness at each stroke position. This will give an enlarged operational weather window and the probability of slack slings and/or high DAF will be significantly reduced even for the most challenging objects.

CAST is particularly useful for objects with large horizontal surfaces (e.g. manifolds, templates and suction anchors) and objects with high buoyancy compared to weight (e.g. protection covers and mud mats).

Monitoring & Logging

Monitoring | ROV monitoring and control (e.g. piston lock subsea). System setup via radio or WiFi. Logging of forces, velocities, accelerations, pressures, stroke and temperatures for post-lift download and analysis.

Logging | Logging of all system data, sensor input, forces and movements during operation. Can be used to verify system performance, actual landing speed, splash zone forces etc.

Cranemaster Passive Depth Compensation

A common challenge when using Passive Heave Compensators in deep water, is the deep water pressure pushing the piston back in, resulting in reduced efficiency of the system. This can be solved by utilizing Cranemaster Passive Depth Compensation (CMDC). This is a patented1), robust solution especially made for deep water operations. Stroke remains constant independent of depth and potential resonance during lowering is eliminated. The solution excels in its simplicity, there is no need for a control system.

1)InterMoore Inc., the owner of US patent 7934561 “Depth Compensated Subsea Passive Heave Compensator”, has granted Cranemaster an exclusive worldwide right for the use of this patent.