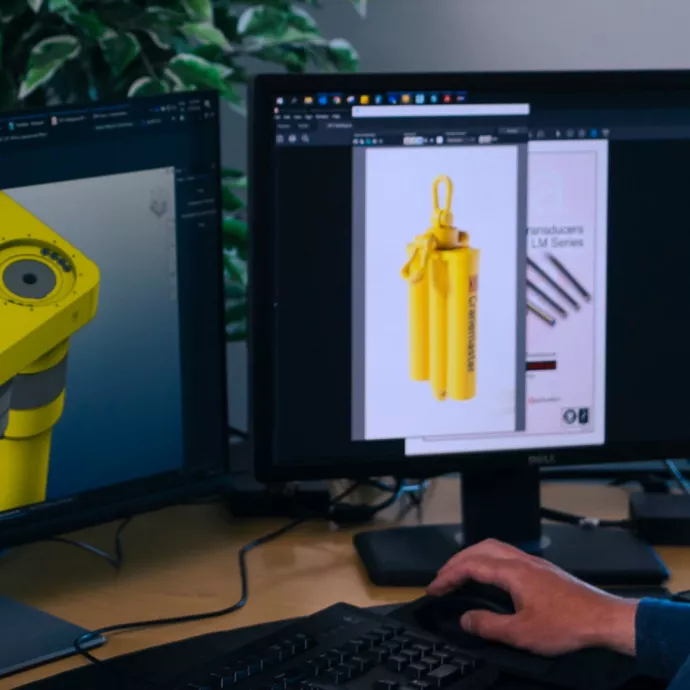

Passive Heave Compensators

Cranemaster's Passive Heave Compensator (PHC) minimises vertical motion and dynamic loads during offshore lifting operations, enabling smooth, controlled lifts.

- Mitigates dynamic loads for enhanced safety

- Extends weather windows for increased operability

- Operates independently of external power sources

Key features

Dynamic load reduction: Minimises dynamic forces to enhance safety during lifts.

Operational flexibility: Reliable performance in rough seas, extending weather windows.

Fail-safe design: Passive, robust functionality ensures continuous operation.

Cost-efficient: Reduces wear on equipment, lowering maintenance costs and minimising downtime.

Easy integration: Compatible with a wide range of lifting systems and offshore configurations.

Benefits

Enhanced Safety

Passive heave compensators protect cranes, rigging, and payloads by reducing dynamic impacts during lifting operations, minimizing the risk of structural damage.

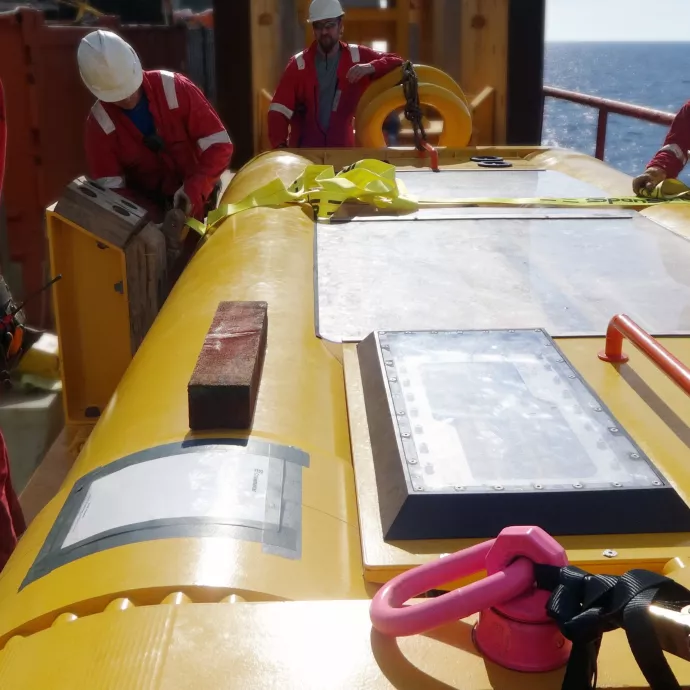

Operational Efficiency

By stabilizing loads and reducing resonance, the units extend weather windows and improve operability, ensuring smoother and more predictable offshore lifts.

Versatile Applications

Ideal for offshore operations such as pile run protection, tension control, and decommissioning. The wide load range and high SWL (up to 1100t) make them suitable for a variety of tasks.

Robust and Reliable

Manufactured in Norway and Germany, these units use high-quality components, ensuring durability and consistent performance under extreme conditions.

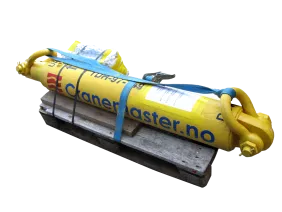

CM1-25T-1000-A

Cranemaster Unit with a safe working load (SWL) of 25 ton and 1000 mm stroke range.

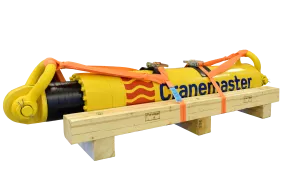

CM1-25T-1000-B

Cranemaster Unit with a safe working load (SWL) of 25 ton and 1000 mm stroke range.

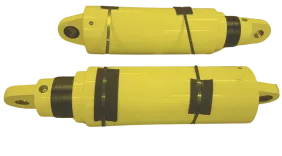

CM1-35T-500-A

Cranemaster Unit with a safe working load (SWL) if 35 ton and 500 mm stroke range.

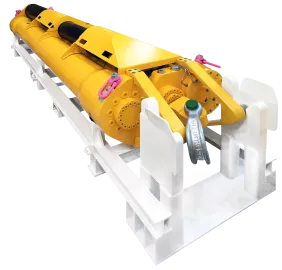

CM1-100T-1000-A

Cranemaster Unit with a safe working load (SWL) of 100 ton and 1000 mm stroke range.

CM1-100T-1000-HP

Cranemaster Unit with a safe working load (SWL) of 100 ton and 1000 mm stroke range.

CM1-100T-2500-A

Cranemaster Unit with a safe working load (SWL) of 100 ton and 2500 mm stroke range.

CM2-50T-3000-A

Cranemaster Unit with a safe working load (SWL) of 50 ton and 3000 mm stroke range.

CM2-150T-3000-A

Cranemaster Unit with a safe working load (SWL) of 150 ton and 3000 mm stroke range.

CM2-150T-4500-A

Cranemaster Unit with a safe working load (SWL) of 150 ton and 4500 mm stroke range.

CM3-25T-3000-A

Cranemaster Unit with a safe working load (SWL) of 25 ton and 3000 mm stroke range.

CM3-50T-3500-A

Cranemaster Unit with a safe working load (SWL) of 50 ton and 3500 mm stroke range.

CM3-75T-4000-A

Cranemaster Unit with a safe working load (SWL) of 75 ton and 4000 mm stroke range.

CM3-75T-4000-DC

Cranemaster Unit with a safe working load (SWL) of 75 ton and 4000 mm stroke range.

CM3-250T-2500-A

Cranemaster Unit with a safe working load (SWL) of 250 ton and 2500 mm stroke range.

CM3-250T-4500-A

Cranemaster Unit with a safe working load (SWL) of 250 ton and 4500 mm stroke range.

CM3-400T-2500-A

Cranemaster Unit with a safe working load (SWL) of 400 ton and 2500 mm stroke range.

CM3-400T-4200-A

Cranemaster Unit with a safe working load (SWL) of 400 ton and 4200 mm stroke range.

CM3-400T-4200-B

Cranemaster Unit with a safe working load (SWL) of 400 ton and 4200 mm stroke range.

CM3-500T-4500-A

Cranemaster Unit with a safe working load (SWL) of 500 ton and 4500 mm stroke range.

CM3-600T-3000-A

Cranemaster Unit with a safe working load (SWL) of 600 ton and 3000 mm stroke range.

CM3-1100T-3000-A

Passive heave compensator / shock absorber with SWL 1100t and 3000 mm stroke range.Passive heave compensator / shock absorber with SWL 1100t and 3000 mm stroke range.

CM3-1000T-4000-A

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4000 mm stroke range.

CM3-1000T-4300-A

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4300 mm stroke range.

CM3-1000T-4300-B

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4300 mm stroke range.

CM3-700T-4500-A

Cranemaster Unit with a safe working load (SWL) of 700 ton and 4500 mm stroke range.

CM3-1100T-4500-B

Cranemaster Unit with a safe working load (SWL) of 1100 ton and 4500 mm stroke range.

CM3-3000T-5500-A

The Cranemaster 3000T-5500-A absorbs energy of the falling hammer and reduces DAF to a manageable level in OW Installations at more challenging areas.

Services

Engineering Services

Operational support

Workshop

Ready to optimize your offshore lifting operations?

Contact our experts today to find the perfect Cranemaster solution for your next project!