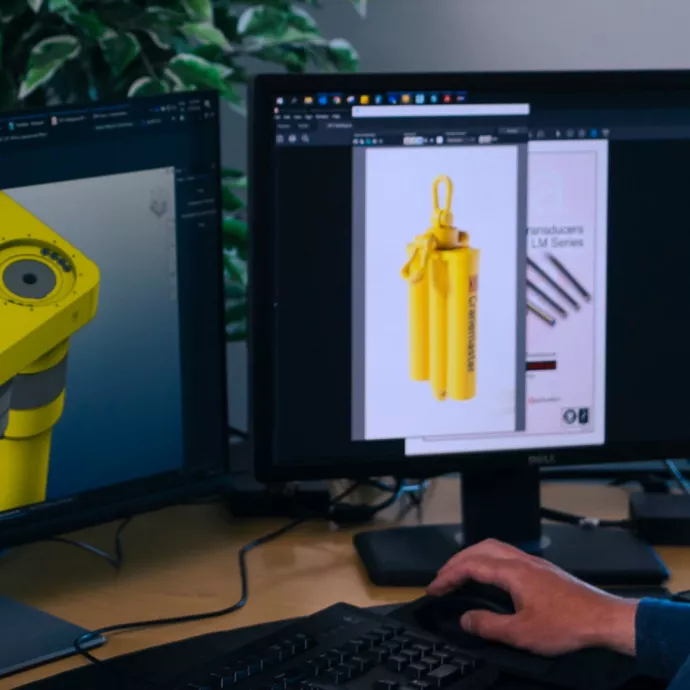

Optimise Decommissioning with Cranemaster®

- Enhanced Safety

- Operational Efficiency

- Tailored Solutions

Cranemaster® Benefits

Cranemaster enhances decommissioning operations by boosting safety, efficiency, and reliability. Its passive heave compensation technology enables controlled lifting in challenging conditions, effectively reducing risks and minimising delays. With customised solutions tailored to the unique requirements of each project, Cranemaster ensures a smoother, more efficient decommissioning process from start to finish.

Reliable Solutions for Complex Decommissioning Challenges

Cranemaster® units are designed to address the unique demands of decommissioning projects. By compensating for heave motions, they eliminate potential snap loads and slack slings during the removal of objects from platforms or subsea environments. During cutting operations, Cranemaster® provides consistent tension in the crane wire, independent of vessel movement, ensuring precise control and safety. For subsea tasks, our units significantly reduce motion, adapting to the shape of the object being handled.

Integrating Cranemaster® into your decommissioning strategy enhances safety, efficiency, and control, ensuring successful outcomes even in the most challenging environments.

Typical Decom operations where Cranemaster® should be considered

Services

Engineering Services

Operational support

Workshop

Case studies

Speak with an expert

Have questions about which unit is best for your decommissioning operation? Fill out the form, and our team will get back to you to discuss.

Trusted by