Resonance Avoidance

Prevent resonance in deep-water operations. In deep-water lifting, resonance can occur when the wave period aligns with the system frequency of the load and wire, leading to uncontrolled dynamic forces. Incorporating a Cranemaster® unit into the rigging increases the system's resonance period, effectively avoiding these destructive movements.

Operational challenges

Deep-water lifting operations are susceptible to resonance, which occurs when wave periods match the natural frequency of the load and wire system. This can cause severe, uncontrollable dynamic forces that jeopardize equipment, safety, and operational efficiency. Mitigating these forces requires precise adjustments to the system's dynamic response to prevent resonance and ensure stable, controlled lifting in challenging offshore environments.

Speak with an Expert

We can help you find the best solution for your operation. Fill in our contact form and one of our experts will get in touch to discuss.

Cranemaster Benefits

Avoid uncontrolled dynamic forces and escalating movements of load during deep water operations.

System resonance period will be increased with Cranemaster included in the rigging.

(This Orcaflex simulation shows how resonance for deep water lowering can be avoided by use of Cranemaster.)

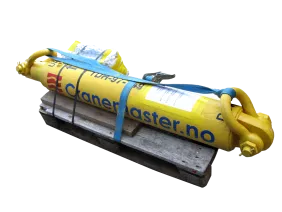

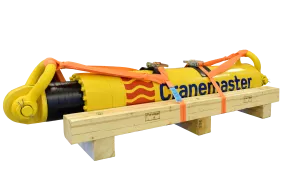

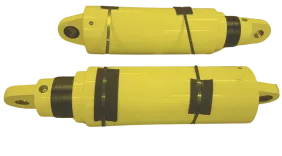

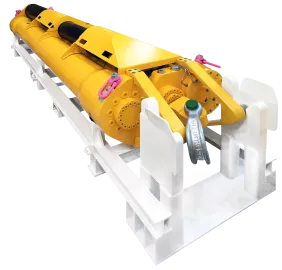

Cranemaster® Passive Heave Compensators

Cranemaster® Passive Heave Compensators enhance offshore lifting by reducing dynamic forces, protecting equipment, and improving safety. These self-contained units expand weather windows and ensure precise load positioning, with capacities up to 1600 tons and stroke lengths up to 5 meters.

Our products

CM1-25T-1000-A

Cranemaster Unit with a safe working load (SWL) of 25 ton and 1000 mm stroke range.

CM1-25T-1000-B

Cranemaster Unit with a safe working load (SWL) of 25 ton and 1000 mm stroke range.

CM1-35T-500-A

Cranemaster Unit with a safe working load (SWL) if 35 ton and 500 mm stroke range.

CM1-100T-1000-A

Cranemaster Unit with a safe working load (SWL) of 100 ton and 1000 mm stroke range.

CM1-100T-1000-HP

Cranemaster Unit with a safe working load (SWL) of 100 ton and 1000 mm stroke range.

CM1-100T-2500-A

Cranemaster Unit with a safe working load (SWL) of 100 ton and 2500 mm stroke range.

CM2-50T-3000-A

Cranemaster Unit with a safe working load (SWL) of 50 ton and 3000 mm stroke range.

CM2-150T-3000-A

Cranemaster Unit with a safe working load (SWL) of 150 ton and 3000 mm stroke range.

CM2-150T-4500-A

Cranemaster Unit with a safe working load (SWL) of 150 ton and 4500 mm stroke range.

CM3-50T-3500-A

Cranemaster Unit with a safe working load (SWL) of 50 ton and 3500 mm stroke range.

CM3-75T-4000-A

Cranemaster Unit with a safe working load (SWL) of 75 ton and 4000 mm stroke range.

CM3-75T-4000-DC

Cranemaster Unit with a safe working load (SWL) of 75 ton and 4000 mm stroke range.

CM3-250T-2500-A

Cranemaster Unit with a safe working load (SWL) of 250 ton and 2500 mm stroke range.

CM3-250T-4500-A

Cranemaster Unit with a safe working load (SWL) of 250 ton and 4500 mm stroke range.

CM3-400T-2500-A

Cranemaster Unit with a safe working load (SWL) of 400 ton and 2500 mm stroke range.

CM3-400T-4200-A

Cranemaster Unit with a safe working load (SWL) of 400 ton and 4200 mm stroke range.

CM3-400T-4200-B

Cranemaster Unit with a safe working load (SWL) of 400 ton and 4200 mm stroke range.

CM3-500T-4500-A

Cranemaster Unit with a safe working load (SWL) of 500 ton and 4500 mm stroke range.

CM3-600T-3000-A

Cranemaster Unit with a safe working load (SWL) of 600 ton and 3000 mm stroke range.

CM3-1100T-3000-A

Passive heave compensator / shock absorber with SWL 1100t and 3000 mm stroke range.Passive heave compensator / shock absorber with SWL 1100t and 3000 mm stroke range.

CM3-1000T-4000-A

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4000 mm stroke range.

CM3-1000T-4300-A

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4300 mm stroke range.

CM3-1000T-4300-B

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4300 mm stroke range.

CM3-700T-4500-A

Cranemaster Unit with a safe working load (SWL) of 700 ton and 4500 mm stroke range.

CM3-1100T-4500-B

Cranemaster Unit with a safe working load (SWL) of 1100 ton and 4500 mm stroke range.

CM3-3000T-5500-A

The Cranemaster 3000T-5500-A absorbs energy of the falling hammer and reduces DAF to a manageable level in OW Installations at more challenging areas.

Speak with an Expert

We can help you find the best solution for your operation. Fill in our contact form and one of our experts will get in touch to discuss.