Special Applications

Cranemaster® units have been utilized in a wide range of special applications over the past four decades. These include impact dampers, shock absorbers for FPSO buoys, load testing, permanent crane installations, custom-made shock absorbers for lifeboats, and geo-survey applications. Our expertise ensures that we can provide customized solutions to meet the specific needs of your offshore operations.

Impact Dampers

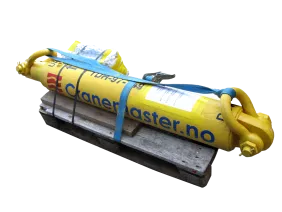

Cranemaster® impact dampers are designed to reduce forces from sudden impacts, protecting cranes, rigging, and payloads during operations like subsea installations or precise landings. Each unit is tailored to meet specific customer requirements, ensuring optimal performance and reliability in demanding offshore environments.

Shock absorbers for FPSO buoy / turret / mooring

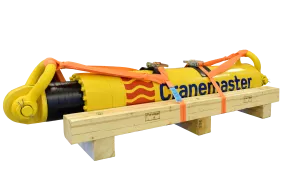

Cranemaster® shock absorbers reduce dynamic forces on FPSO buoys, turrets, and mooring lines, mitigating shocks from waves, wind, and currents. Tailored to customer needs, they enhance safety, extend equipment lifespan, and ensure reliable performance in harsh offshore environments.

Load testing

Cranemaster® units enhance load testing by simulating dynamic forces, replicating real-world conditions like wave-induced loads or sudden shifts. They protect equipment by absorbing peak forces, ensuring safe and accurate testing. Tailored to specific needs, these units provide adjustable damping for efficient and realistic performance validation.

Permanent installations in crane

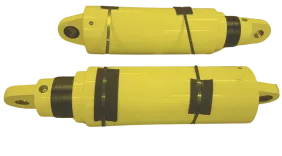

Cranemaster® shock absorbers can be permanently integrated into cranes to reduce peak loads, minimize wear, and extend equipment lifespan. Tailored for offshore operations, they enhance safety, improve lifting performance, and lower maintenance costs by continuously managing dynamic forces.

Speak with an expert

We can help you find the best solution for your operation. Fill in our contact form and one of our experts will get in touch to discuss.

Custom made shock absorbers for life boats

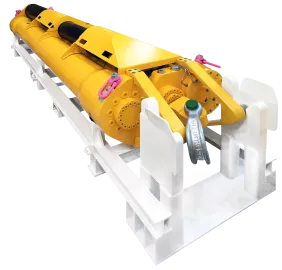

Cranemaster® custom shock absorbers ensure safe and reliable lifeboat launch and recovery by reducing impact forces and protecting equipment and crew. Tailored to specific needs, they deliver robust performance in harsh conditions, meeting safety standards and enhancing operational confidence.

Our products

CM1-25T-1000-A

Cranemaster Unit with a safe working load (SWL) of 25 ton and 1000 mm stroke range.

CM1-25T-1000-B

Cranemaster Unit with a safe working load (SWL) of 25 ton and 1000 mm stroke range.

CM1-35T-500-A

Cranemaster Unit with a safe working load (SWL) if 35 ton and 500 mm stroke range.

CM1-100T-1000-A

Cranemaster Unit with a safe working load (SWL) of 100 ton and 1000 mm stroke range.

CM1-100T-1000-HP

Cranemaster Unit with a safe working load (SWL) of 100 ton and 1000 mm stroke range.

CM1-100T-2500-A

Cranemaster Unit with a safe working load (SWL) of 100 ton and 2500 mm stroke range.

CM2-50T-3000-A

Cranemaster Unit with a safe working load (SWL) of 50 ton and 3000 mm stroke range.

CM2-150T-3000-A

Cranemaster Unit with a safe working load (SWL) of 150 ton and 3000 mm stroke range.

CM2-150T-4500-A

Cranemaster Unit with a safe working load (SWL) of 150 ton and 4500 mm stroke range.

CM3-50T-3500-A

Cranemaster Unit with a safe working load (SWL) of 50 ton and 3500 mm stroke range.

CM3-75T-4000-A

Cranemaster Unit with a safe working load (SWL) of 75 ton and 4000 mm stroke range.

CM3-75T-4000-DC

Cranemaster Unit with a safe working load (SWL) of 75 ton and 4000 mm stroke range.

CM3-250T-2500-A

Cranemaster Unit with a safe working load (SWL) of 250 ton and 2500 mm stroke range.

CM3-250T-4500-A

Cranemaster Unit with a safe working load (SWL) of 250 ton and 4500 mm stroke range.

CM3-400T-2500-A

Cranemaster Unit with a safe working load (SWL) of 400 ton and 2500 mm stroke range.

CM3-400T-4200-A

Cranemaster Unit with a safe working load (SWL) of 400 ton and 4200 mm stroke range.

CM3-400T-4200-B

Cranemaster Unit with a safe working load (SWL) of 400 ton and 4200 mm stroke range.

CM3-500T-4500-A

Cranemaster Unit with a safe working load (SWL) of 500 ton and 4500 mm stroke range.

CM3-600T-3000-A

Cranemaster Unit with a safe working load (SWL) of 600 ton and 3000 mm stroke range.

CM3-1100T-3000-A

Passive heave compensator / shock absorber with SWL 1100t and 3000 mm stroke range.Passive heave compensator / shock absorber with SWL 1100t and 3000 mm stroke range.

CM3-1000T-4000-A

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4000 mm stroke range.

CM3-1000T-4300-A

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4300 mm stroke range.

CM3-1000T-4300-B

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4300 mm stroke range.

CM3-700T-4500-A

Cranemaster Unit with a safe working load (SWL) of 700 ton and 4500 mm stroke range.

CM3-1100T-4500-B

Cranemaster Unit with a safe working load (SWL) of 1100 ton and 4500 mm stroke range.

CM3-3000T-5500-A

The Cranemaster 3000T-5500-A absorbs energy of the falling hammer and reduces DAF to a manageable level in OW Installations at more challenging areas.

Speak with an expert

We can help you find the best solution for your operation. Fill in our contact form and one of our experts will get in touch to discuss.