Quick Lift

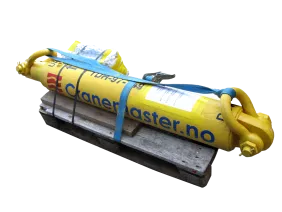

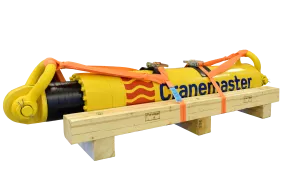

Cranemaster's Quick Lift functionality prevents re-contact of the load with the deck due to vessel heeling after lift-off. This feature is part of the Cranemaster Adaptive Control System, ensuring safe and efficient lifting operations.

Operational challenges

Offshore lifting operations often face challenges such as vessel heeling after lift-off, which can cause re-contact between the load and the deck. This increases the risk of damage to equipment and delays in operations. Additionally, maintaining stability and avoiding sudden load shifts during lift-off require precise control, especially in dynamic environments. These challenges necessitate advanced solutions to ensure safe, efficient, and uninterrupted lifting processes.

Cranemaster Benefits

Using accumulator stored pressure to provide additional lifting during lift-off from barge or supply vessel.

The Quick Lift functionality will lift the load by pulling in the piston and thereby avoiding re-contact.

Solution for WTG feeder

Background:

Installation vessels are expensive assets and their main work is to do installation work offshore; not transporting components. Such transportation can be done by using a cheaper feeder barge or vessel. This is something already been used in offshore wind foundations and other market like oil & gas.

Another particular situation is the Jones Act regulation which is applicable in the US, where non-US installation vessels can not enter a US port for picking up the Wind Turbine Components (WTG) for following doing the installation.

The physical challenges:

As feeder vessels or barges move on the waves (heave), relative motions between the installation vessel and the heaving barge need to be handled.

The solution

Cranemaster can contribute to feeder objects like Wind Turbine Components (WTG) from shore to the installation vessel. As the feeder vessel or barge is heaving, motions needs to be handled. Cranemaster has a solution for this, by first providing a smooth tensioning of the rigging, avoiding shock loads, secondly, compensate for heaving. As installation vessel cranes have slow hoisting speed, there is a risk of re-contact dyring the lift-off following the upwards heave of the feeder vessel. The Quick Lift feature of Cranemaster can solve this problem by a fast retraction of the piston rod, enabling sufficient lifting speed and height to secure that there is no re-contact.

Field Proven

Cranemaster has a track record of nearly 1000 offshore heavy lift projects and know the offshore heavy lift challenges. During more than a decade, Cranemaster Quick Lift technology has been used in the offshore Oil & Gas industry. Since then, we have improved and refined this technology with several add-on features*. Recently Quick lift has demonstrated it’s value also during Offshore Wind farm installation. In addition to extensive testing and data, we have a unique and solid track record of this technology.

Capacity

Quick Lift can be retrofitted to the majority of our Cranemaster tools. Thus, be quickly available based on a long history of well proven and robust Cranemaster technology.

Find the right Cranemaster

We can help you find the best solution for your operation. Fill in our contact form and one of our experts will get in touch to discuss.

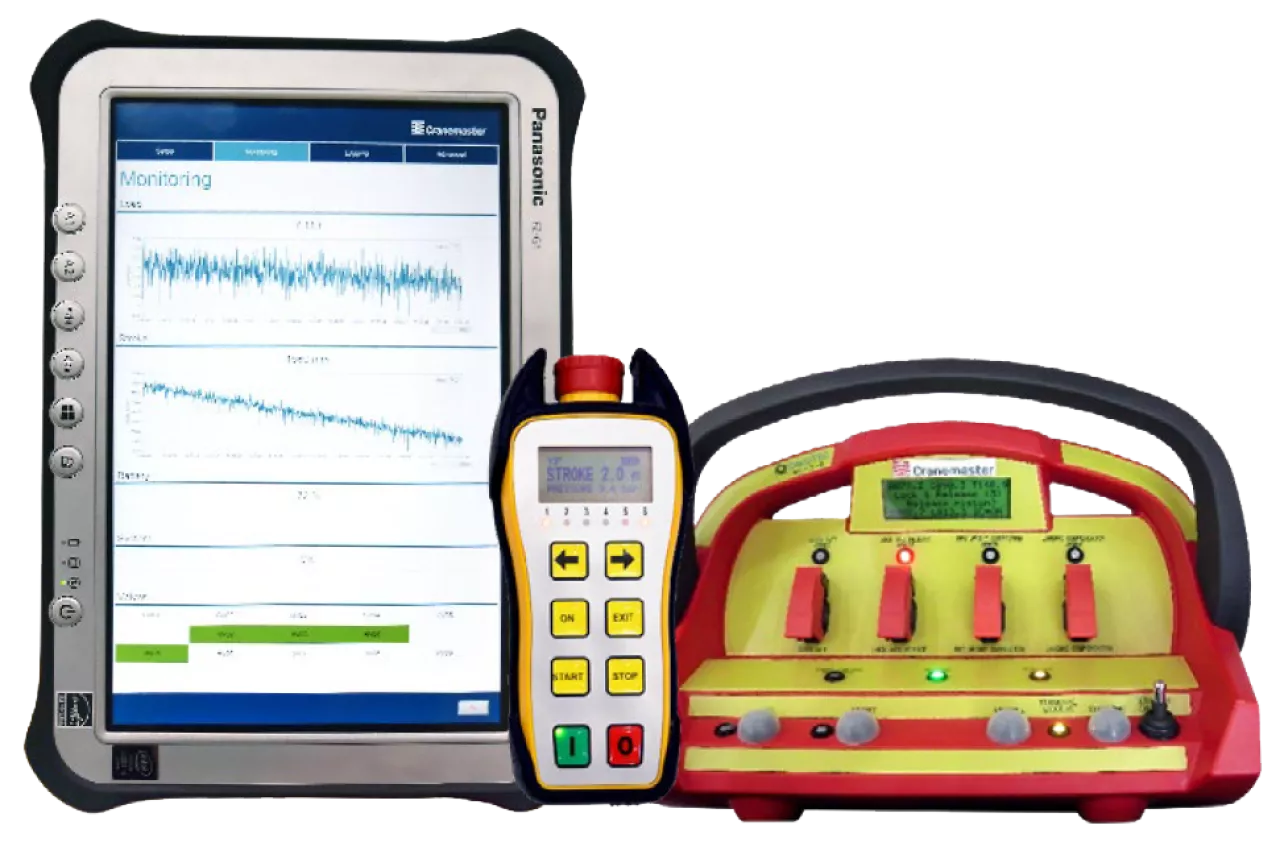

Control systems

Cranemaster® Control Systems enhance safety and performance in offshore lifting with advanced features like Quick Lift, Depth Compensation, and CMAC for adaptive adjustments. DNV GL-certified, these systems ensure efficiency, reliability, and compliance with industry standards.

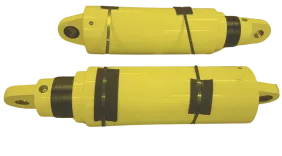

Our products

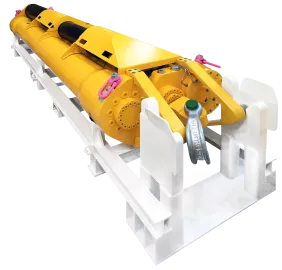

CM1-25T-1000-A

Cranemaster Unit with a safe working load (SWL) of 25 ton and 1000 mm stroke range.

CM1-25T-1000-B

Cranemaster Unit with a safe working load (SWL) of 25 ton and 1000 mm stroke range.

CM1-35T-500-A

Cranemaster Unit with a safe working load (SWL) if 35 ton and 500 mm stroke range.

CM1-100T-1000-A

Cranemaster Unit with a safe working load (SWL) of 100 ton and 1000 mm stroke range.

CM1-100T-1000-HP

Cranemaster Unit with a safe working load (SWL) of 100 ton and 1000 mm stroke range.

CM1-100T-2500-A

Cranemaster Unit with a safe working load (SWL) of 100 ton and 2500 mm stroke range.

CM2-50T-3000-A

Cranemaster Unit with a safe working load (SWL) of 50 ton and 3000 mm stroke range.

CM2-150T-3000-A

Cranemaster Unit with a safe working load (SWL) of 150 ton and 3000 mm stroke range.

CM2-150T-4500-A

Cranemaster Unit with a safe working load (SWL) of 150 ton and 4500 mm stroke range.

CM3-50T-3500-A

Cranemaster Unit with a safe working load (SWL) of 50 ton and 3500 mm stroke range.

CM3-75T-4000-A

Cranemaster Unit with a safe working load (SWL) of 75 ton and 4000 mm stroke range.

CM3-75T-4000-DC

Cranemaster Unit with a safe working load (SWL) of 75 ton and 4000 mm stroke range.

CM3-250T-2500-A

Cranemaster Unit with a safe working load (SWL) of 250 ton and 2500 mm stroke range.

CM3-250T-4500-A

Cranemaster Unit with a safe working load (SWL) of 250 ton and 4500 mm stroke range.

CM3-400T-2500-A

Cranemaster Unit with a safe working load (SWL) of 400 ton and 2500 mm stroke range.

CM3-400T-4200-A

Cranemaster Unit with a safe working load (SWL) of 400 ton and 4200 mm stroke range.

CM3-400T-4200-B

Cranemaster Unit with a safe working load (SWL) of 400 ton and 4200 mm stroke range.

CM3-500T-4500-A

Cranemaster Unit with a safe working load (SWL) of 500 ton and 4500 mm stroke range.

CM3-600T-3000-A

Cranemaster Unit with a safe working load (SWL) of 600 ton and 3000 mm stroke range.

CM3-1100T-3000-A

Passive heave compensator / shock absorber with SWL 1100t and 3000 mm stroke range.Passive heave compensator / shock absorber with SWL 1100t and 3000 mm stroke range.

CM3-1000T-4000-A

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4000 mm stroke range.

CM3-1000T-4300-A

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4300 mm stroke range.

CM3-1000T-4300-B

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4300 mm stroke range.

CM3-700T-4500-A

Cranemaster Unit with a safe working load (SWL) of 700 ton and 4500 mm stroke range.

CM3-1100T-4500-B

Cranemaster Unit with a safe working load (SWL) of 1100 ton and 4500 mm stroke range.

CM3-3000T-5500-A

The Cranemaster 3000T-5500-A absorbs energy of the falling hammer and reduces DAF to a manageable level in OW Installations at more challenging areas.

Find the right Cranemaster

We can help you find the best solution for your operation. Fill in our contact form and one of our experts will get in touch to discuss.