Transfer Lift

Cranemaster® units mitigate dynamic loads during transfer lifts, protecting cranes and structures by reducing the dynamic amplification factor (DAF) in all lifting phases. This ensures smoother operations and extends the operational weather window.

Operational challenges

Offshore lifting operations are often challenged by dynamic loads, harsh weather, and unpredictable forces—especially during transfer lifts between vessels or installations. These lifts are highly affected by wave motion, increasing the Dynamic Amplification Factor (DAF) and the risk of overload or equipment damage. Managing these forces is critical to ensuring safe, efficient operations and extending the usable weather window.

Key challenges:

Dynamic loads on crane or load at lift-off

Limited operational weather window due to harsh sea conditions

High risk during re-entry of lifted load

Peak loads threatening cranes, rigging, and payloads

Transfer lifts impacted by wave-induced motions and high DAF

Cranemaster Benefits

Increasing the operational weather window of the lifting operation

Protection of crane and lifted structure in all lifting phases by reducing the dynamic amplification factor (DAF)

Immediate response to potential dangerous loads

Enabling crane to maintain its lifting capacity at increased wave height

Offloading from a supply vessel or barge with and without Cranemaster

This Orcaflex simulation shows a lift-off situation from a barge. The crane is sitting on a fixed platform, but the principles are the same also if the crane is mounted on a moving vessel.

Without Cranemaster (to the left):

Significant snap load during lift-off, in this case around 85T. This corresponds to a DAF of 1.7.

With Cranemaster (to the right):

Snap load is avoided and the DAF is reduced to around 1.1.

For cranes with a slow lifting speed, there may be a risk of re-contact between the structure and the barge. Some Cranemaster units can be equipped with a quick-lift system which will pull in the piston and thereby avoiding the re-contact.

Tackle Dynamic Load Challenges

Get expert advice but clicking the button below.

Shock absorption since 1983

The first applications of Cranemaster units back in the early 1980s were related to shock absorption and since then small units with SWL of a few ton up to large units with SWL of 500 ton have been developed.

Please contact us for discussions of specially designed Cranemaster units used for shock absorption.

MOB boats, lifeboats and NORSOK R-002

Over the years Cranemaster has delivered a number of different units for deployment/retrieval of MOB, work boats, and lifeboats. In the NORSOK R-002, edition 2. issued in September 2012 there are strict rules for shock absorption during lifting of MOB boats and lifeboats.

Cranemaster is an excellent solution to these requirements, and is well suited in cases where the use of elastic pennant is impractical or does not give sufficient dampening.

Cranemaster® shock absorber

A Cranemaster® shock absorber protects cranes and rigging from snap loads during piling, reducing the risk of costly interruptions while protecting equipment and enhancing safety. Developed in collaboration with industry leaders, these shock absorbers offer proven performance, including up to a 60% decrease in dynamic hook loads.

Our products

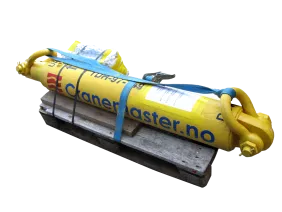

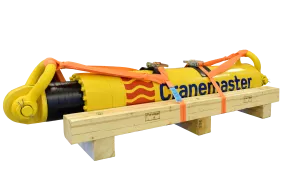

CM1-25T-1000-A

Cranemaster Unit with a safe working load (SWL) of 25 ton and 1000 mm stroke range.

CM1-25T-1000-B

Cranemaster Unit with a safe working load (SWL) of 25 ton and 1000 mm stroke range.

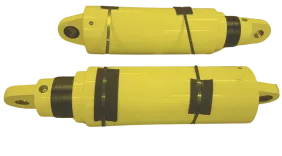

CM1-35T-500-A

Cranemaster Unit with a safe working load (SWL) if 35 ton and 500 mm stroke range.

CM1-100T-1000-A

Cranemaster Unit with a safe working load (SWL) of 100 ton and 1000 mm stroke range.

CM1-100T-1000-HP

Cranemaster Unit with a safe working load (SWL) of 100 ton and 1000 mm stroke range.

CM1-100T-2500-A

Cranemaster Unit with a safe working load (SWL) of 100 ton and 2500 mm stroke range.

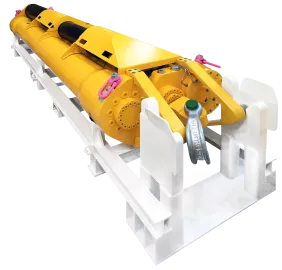

CM2-50T-3000-A

Cranemaster Unit with a safe working load (SWL) of 50 ton and 3000 mm stroke range.

CM2-150T-3000-A

Cranemaster Unit with a safe working load (SWL) of 150 ton and 3000 mm stroke range.

CM2-150T-4500-A

Cranemaster Unit with a safe working load (SWL) of 150 ton and 4500 mm stroke range.

CM3-50T-3500-A

Cranemaster Unit with a safe working load (SWL) of 50 ton and 3500 mm stroke range.

CM3-75T-4000-A

Cranemaster Unit with a safe working load (SWL) of 75 ton and 4000 mm stroke range.

CM3-75T-4000-DC

Cranemaster Unit with a safe working load (SWL) of 75 ton and 4000 mm stroke range.

CM3-250T-2500-A

Cranemaster Unit with a safe working load (SWL) of 250 ton and 2500 mm stroke range.

CM3-250T-4500-A

Cranemaster Unit with a safe working load (SWL) of 250 ton and 4500 mm stroke range.

CM3-400T-2500-A

Cranemaster Unit with a safe working load (SWL) of 400 ton and 2500 mm stroke range.

CM3-400T-4200-A

Cranemaster Unit with a safe working load (SWL) of 400 ton and 4200 mm stroke range.

CM3-400T-4200-B

Cranemaster Unit with a safe working load (SWL) of 400 ton and 4200 mm stroke range.

CM3-500T-4500-A

Cranemaster Unit with a safe working load (SWL) of 500 ton and 4500 mm stroke range.

CM3-600T-3000-A

Cranemaster Unit with a safe working load (SWL) of 600 ton and 3000 mm stroke range.

CM3-1100T-3000-A

Passive heave compensator / shock absorber with SWL 1100t and 3000 mm stroke range.Passive heave compensator / shock absorber with SWL 1100t and 3000 mm stroke range.

CM3-1000T-4000-A

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4000 mm stroke range.

CM3-1000T-4300-A

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4300 mm stroke range.

CM3-1000T-4300-B

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4300 mm stroke range.

CM3-700T-4500-A

Cranemaster Unit with a safe working load (SWL) of 700 ton and 4500 mm stroke range.

CM3-1100T-4500-B

Cranemaster Unit with a safe working load (SWL) of 1100 ton and 4500 mm stroke range.

CM3-3000T-5500-A

The Cranemaster 3000T-5500-A absorbs energy of the falling hammer and reduces DAF to a manageable level in OW Installations at more challenging areas.

Find the right Cranemaster

We can help you find the best solution for your operation. Fill in our contact form and one of our experts will get in touch to discuss.