Posted in Projects

Deep water pressure testing

Posted in Projects

Deep water puts enormous pressure on underwater equipment so testing prior to deployment is crucial to ensure all components can withstand it. This week we did a pressure test of components for a new challenging project where work will be performed at water depths greater than 1600 meters.

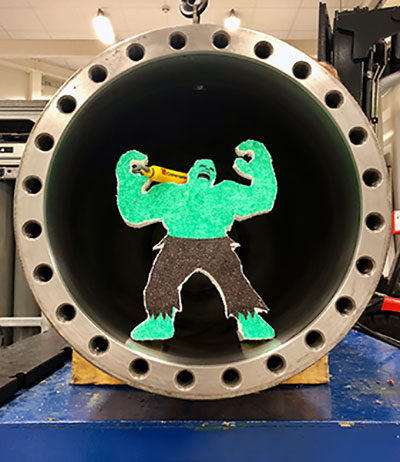

The Cranemaster test facilities have a deep water hyperbaric pressure testing chamber where we test the integrity of subsea components and instruments by simulating various water depths. We decided to have some fun, and put The Hulk up for a challenge. Would he tackle the water depths as good as the Cranemaster components? He spent one night in the test chamber and reached a depth of 3000 meter.

Why did The Hulk shrink?

Hydrostatic pressure, or the pressure exerted by a fluid due to gravity, increases with depth. With every meter increase in depth, additional kg of force is placed on an object. Cranemaster units, with all of its components, are specially designed so that they can operate under extreme pressures. The Hulk, however, is made of the easily compressible material polystyrene. This material consists of air-filled bubbles stuck together. At great water depths, the air that fills the tiny bubbles is compressed, crushing the bubbles and shrinking The Hulk. The compression is uniform, and thanks to this The Hulk looks almost the same in shape, but not in size.

PS! As expected, all the Cranemaster components passed the pressure test just fine and are now ready for challenging operations.