Tension Control

Cranemaster® ensures consistent tension control, safeguarding equipment and enhancing operational precision in challenging offshore and marine environments.

Key Operations

Cranemaster® technology provides advanced tension management to address the complexities of offshore and marine lifting, offering reliability and safety across diverse applications:

Constant Tension in Dynamic Conditions: Maintain stable wire tension during operations, compensating for vessel heave and preventing slack or snap loads.

Controlled Lift-Off Dynamics: Reduce dynamic amplification factors (DAF) for smooth and safe lift-off procedures, even in rough seas.

Splash Zone Stability: Minimise risks of slack slings when lowering heavy loads through the splash zone, ensuring precise handling.

Subsea Operations: Ensure consistent tension for safe lowering, landing, or recovery of subsea structures, protecting cranes and rigging from excessive forces.

Cutting and Sawing Support: Achieve continuous tension during cutting operations, improving safety and operational efficiency.

Cranemaster’s tailored solutions deliver unparalleled tension control, helping offshore and marine projects achieve operational success while protecting valuable assets in demanding conditions.

Cranemaster Benefits

Constant tension despite vessel movements.

Fail safe constant tension functionality.

Works as a constant tension system, but with added dampening preventing abrupt movements.

Overload protection.

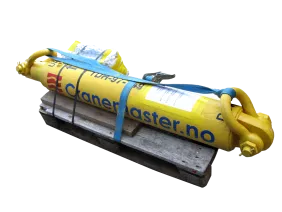

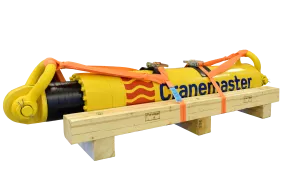

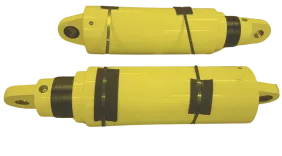

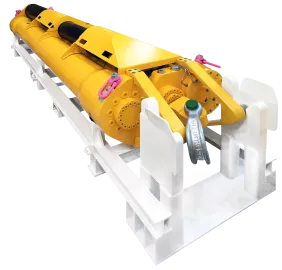

Cranemaster® Passive Heave Compensators

Cranemaster® Passive Heave Compensators enhance offshore lifting by reducing dynamic forces, protecting equipment, and improving safety. These self-contained units expand weather windows and ensure precise load positioning, with capacities up to 1600 tons and stroke lengths up to 5 meters.

Our products

CM1-25T-1000-A

Cranemaster Unit with a safe working load (SWL) of 25 ton and 1000 mm stroke range.

CM1-25T-1000-B

Cranemaster Unit with a safe working load (SWL) of 25 ton and 1000 mm stroke range.

CM1-35T-500-A

Cranemaster Unit with a safe working load (SWL) if 35 ton and 500 mm stroke range.

CM1-100T-1000-A

Cranemaster Unit with a safe working load (SWL) of 100 ton and 1000 mm stroke range.

CM1-100T-1000-HP

Cranemaster Unit with a safe working load (SWL) of 100 ton and 1000 mm stroke range.

CM1-100T-2500-A

Cranemaster Unit with a safe working load (SWL) of 100 ton and 2500 mm stroke range.

CM2-50T-3000-A

Cranemaster Unit with a safe working load (SWL) of 50 ton and 3000 mm stroke range.

CM2-150T-3000-A

Cranemaster Unit with a safe working load (SWL) of 150 ton and 3000 mm stroke range.

CM2-150T-4500-A

Cranemaster Unit with a safe working load (SWL) of 150 ton and 4500 mm stroke range.

CM3-50T-3500-A

Cranemaster Unit with a safe working load (SWL) of 50 ton and 3500 mm stroke range.

CM3-75T-4000-A

Cranemaster Unit with a safe working load (SWL) of 75 ton and 4000 mm stroke range.

CM3-75T-4000-DC

Cranemaster Unit with a safe working load (SWL) of 75 ton and 4000 mm stroke range.

CM3-250T-2500-A

Cranemaster Unit with a safe working load (SWL) of 250 ton and 2500 mm stroke range.

CM3-250T-4500-A

Cranemaster Unit with a safe working load (SWL) of 250 ton and 4500 mm stroke range.

CM3-400T-2500-A

Cranemaster Unit with a safe working load (SWL) of 400 ton and 2500 mm stroke range.

CM3-400T-4200-A

Cranemaster Unit with a safe working load (SWL) of 400 ton and 4200 mm stroke range.

CM3-400T-4200-B

Cranemaster Unit with a safe working load (SWL) of 400 ton and 4200 mm stroke range.

CM3-500T-4500-A

Cranemaster Unit with a safe working load (SWL) of 500 ton and 4500 mm stroke range.

CM3-600T-3000-A

Cranemaster Unit with a safe working load (SWL) of 600 ton and 3000 mm stroke range.

CM3-1100T-3000-A

Passive heave compensator / shock absorber with SWL 1100t and 3000 mm stroke range.Passive heave compensator / shock absorber with SWL 1100t and 3000 mm stroke range.

CM3-1000T-4000-A

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4000 mm stroke range.

CM3-1000T-4300-A

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4300 mm stroke range.

CM3-1000T-4300-B

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4300 mm stroke range.

CM3-700T-4500-A

Cranemaster Unit with a safe working load (SWL) of 700 ton and 4500 mm stroke range.

CM3-1100T-4500-B

Cranemaster Unit with a safe working load (SWL) of 1100 ton and 4500 mm stroke range.

CM3-3000T-5500-A

The Cranemaster 3000T-5500-A absorbs energy of the falling hammer and reduces DAF to a manageable level in OW Installations at more challenging areas.

Speak with an expert

We can help you find the best solution for your operation. Fill in our contact form and one of our experts will get in touch to discuss.