Subsea Landing

Enhance Subsea Landings with Cranemaster®. As subsea structures become larger and more complex, controlling landing speed is crucial. Cranemaster® units effectively reduce motion during subsea lifting operations by absorbing boom tip movements, ensuring smooth and precise landings.

Operational challenges

Subsea landing operations are increasingly demanding as structures grow larger and more complex. Precise control of landing speed is critical to avoid damage to equipment and subsea installations. Factors such as vessel movement, hydrodynamic forces, and limited visibility further complicate operations, increasing the risk of impact or misalignment during placement. Advanced solutions are required to mitigate these challenges and ensure safe and accurate landings.

Cranemaster Benefits

By using a Cranemaster unit during the subsea landing, the operation will benefit from:

Reduction of landing speed.

Possibility to maintain tension in wire during landing phase.

Reduction of peak loads in case of re-lifting.

Prevention of rapid heeling of vessel during landing of heavy loads.

Subsea Landing With and Without Cranemaster

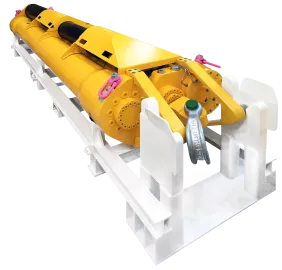

Two 700T Cranemaster units are used in parallel. Actual observed forces and movements corresponded well to the Orcaflex simulation.

Without Cranemaster:

Maximum landing speed = -0,7 m/s

Maximum crane tension = 2000 ton

With Cranemaster:

Maximum landing speed = -0,1 m/s

Maximum crane tension = 840 ton

No slack observed in the rigging

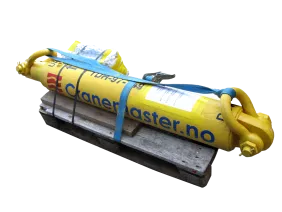

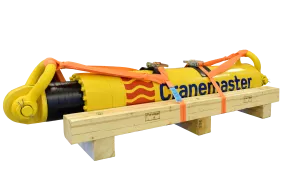

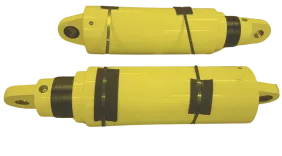

Cranemaster® Passive Heave Compensators

Cranemaster® Passive Heave Compensators enhance offshore lifting by reducing dynamic forces, protecting equipment, and improving safety. These self-contained units expand weather windows and ensure precise load positioning, with capacities up to 1600 tons and stroke lengths up to 5 meters.

Our products

CM1-25T-1000-A

Cranemaster Unit with a safe working load (SWL) of 25 ton and 1000 mm stroke range.

CM1-25T-1000-B

Cranemaster Unit with a safe working load (SWL) of 25 ton and 1000 mm stroke range.

CM1-35T-500-A

Cranemaster Unit with a safe working load (SWL) if 35 ton and 500 mm stroke range.

CM1-100T-1000-A

Cranemaster Unit with a safe working load (SWL) of 100 ton and 1000 mm stroke range.

CM1-100T-1000-HP

Cranemaster Unit with a safe working load (SWL) of 100 ton and 1000 mm stroke range.

CM1-100T-2500-A

Cranemaster Unit with a safe working load (SWL) of 100 ton and 2500 mm stroke range.

CM2-50T-3000-A

Cranemaster Unit with a safe working load (SWL) of 50 ton and 3000 mm stroke range.

CM2-150T-3000-A

Cranemaster Unit with a safe working load (SWL) of 150 ton and 3000 mm stroke range.

CM2-150T-4500-A

Cranemaster Unit with a safe working load (SWL) of 150 ton and 4500 mm stroke range.

CM3-25T-3000-A

Cranemaster Unit with a safe working load (SWL) of 25 ton and 3000 mm stroke range.

CM3-50T-3500-A

Cranemaster Unit with a safe working load (SWL) of 50 ton and 3500 mm stroke range.

CM3-75T-4000-A

Cranemaster Unit with a safe working load (SWL) of 75 ton and 4000 mm stroke range.

CM3-75T-4000-DC

Cranemaster Unit with a safe working load (SWL) of 75 ton and 4000 mm stroke range.

CM3-250T-2500-A

Cranemaster Unit with a safe working load (SWL) of 250 ton and 2500 mm stroke range.

CM3-250T-4500-A

Cranemaster Unit with a safe working load (SWL) of 250 ton and 4500 mm stroke range.

CM3-400T-2500-A

Cranemaster Unit with a safe working load (SWL) of 400 ton and 2500 mm stroke range.

CM3-400T-4200-A

Cranemaster Unit with a safe working load (SWL) of 400 ton and 4200 mm stroke range.

CM3-400T-4200-B

Cranemaster Unit with a safe working load (SWL) of 400 ton and 4200 mm stroke range.

CM3-500T-4500-A

Cranemaster Unit with a safe working load (SWL) of 500 ton and 4500 mm stroke range.

CM3-600T-3000-A

Cranemaster Unit with a safe working load (SWL) of 600 ton and 3000 mm stroke range.

CM3-1100T-3000-A

Passive heave compensator / shock absorber with SWL 1100t and 3000 mm stroke range.Passive heave compensator / shock absorber with SWL 1100t and 3000 mm stroke range.

CM3-1000T-4000-A

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4000 mm stroke range.

CM3-1000T-4300-A

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4300 mm stroke range.

CM3-1000T-4300-B

Cranemaster Unit with a safe working load (SWL) of 1000 ton and 4300 mm stroke range.

CM3-700T-4500-A

Cranemaster Unit with a safe working load (SWL) of 700 ton and 4500 mm stroke range.

CM3-1100T-4500-B

Cranemaster Unit with a safe working load (SWL) of 1100 ton and 4500 mm stroke range.

CM3-3000T-5500-A

The Cranemaster 3000T-5500-A absorbs energy of the falling hammer and reduces DAF to a manageable level in OW Installations at more challenging areas.

Speak with an expert

We can help you find the best solution for your subsea operation. Fill in our contact form and one of our experts will get in touch to discuss.