Find references by:

Wreck removal operation in New Zealand

Customer Challenge: When the MV Rena grounded on Otaiti (Astrolabe Reef) in the Bay of Plenty, it resulted in one of New Zealand’s most significant maritime environmental disasters. The removal process was considered a difficult and risky process. Cranemaster Solution: Cranemaster assisted with calculations and lift simulations prior to the…

Cranemaster used for load test on Normand Seven

Customer Challenge: The vessel Normand Seven was chartered from Solstad Offshore ASA by Subsea 7 and converted into a subsea pipe laying vessel for a long-term contract in Brazilian waters. Subsea 7 looked into ways to dynamically test the flexible pipe tensioner installed on the vessel. Cranemaster Solution: A standard…

Installation of transition pieces at Greater Gabbard

Customer Challenge: Installation of transition pieces from floating vessels can be challenging. For the Greater Gabbard Offshore Wind Farm project off the UK coast, Jumbo Offshore therefore included Cranemaster for the installation of transition pieces. Cranemaster Solution: Two new Cranemaster units with SWL of 400 metric tons and 2,5 meter stroke was designed for…

Transfer lift of a platform module

Customer Challenge: Lifting of a platform structure from a barge onto a platform. Cranemaster Solution: Two Cranemaster units in series with SWL of 400 metric tons and 4,3 meter stroke. Cranemaster Quick Lift functionality was used to avoid re-contact after lift off.

Installation of suction pile in deep water

Customer Challenge: Installation of a 50 metric tons suction pile for the Boabab Phase 3 project outside West Africa. Operations in deep water areas put strong demands on the equipment to be used. A common challenge when using passive heave compensators in deep water, is the deep water pressure pushing…

Strand jack heave compensation

Customer Challenge: Motion compensation during maintenance operation on an FPSO external turret mooring structure off the African west coast. As part of the maintenance operation, a swivel was going to be exchanged. While exchanging the swivel, a strand jack is used to hold together the structure. Cranemaster Solution: To compensate…

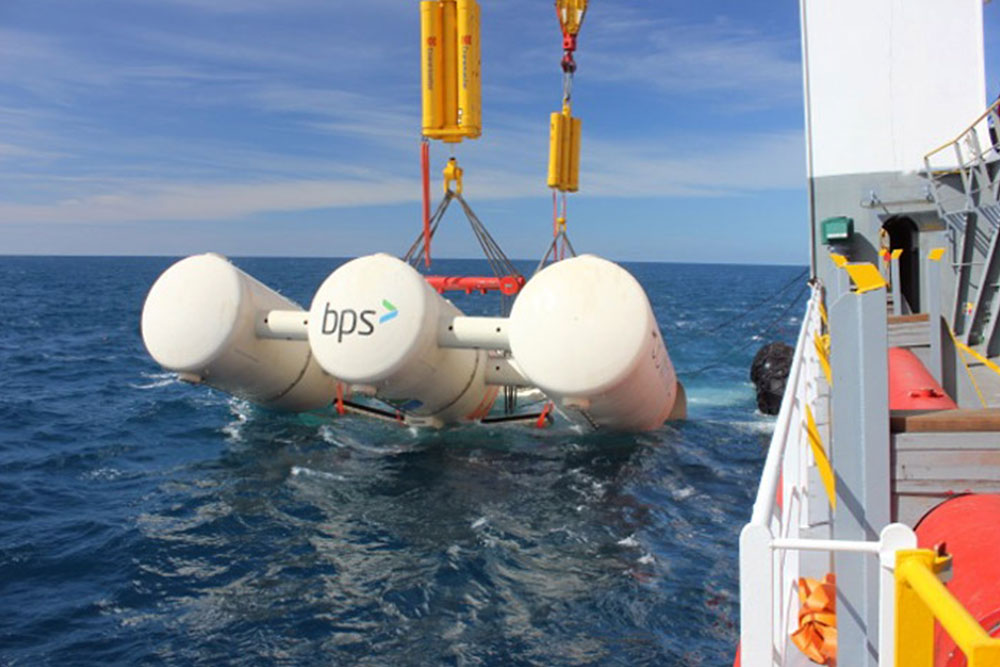

Installation of large wave energy device

Customer Challenge: Installation of the wave energy device bioWAVE near Port Fairy, Victoria, in rough weather conditions. Cranemaster Solution: Two large Cranemaster passive heave compensators with SWL of 700 metric tons and 400 metric tons. The Results: The two Cranemaster units functioned perfectly, resulting in reduced DAF in the splash…

Removal of 420 metric tons offshore bridge structure

Customer Challenge: Protection of the crane and the structure from shock loads during the removal process of a large offshore bridge structure of 420 metric tons in the North Sea. Cranemaster Solution: A Cranemaster unit with SWL of 600 metric tons and 3 meter stroke. The Results: Potential shock loads…

Installation of PLEM modules in the South China Sea

Customer Challenge: Splash zone crossing and reduction in seabed landing velocity during installation of PLEM modules in the South China Sea. Cranemaster Solution: A Cranemaster passive heave compensator with SWL of 150 metric tons and 4,5 meter stroke. The Results: Due to the large horizontal area of the PLEM modules,…

Worlds largest heave compensated lift

Customer Challenge: Enabling installation of large subsea modules of up to 1100 metric tons in higher sea states for the Chevron Gorgon Project. Cranemaster Solution: Two Cranemaster passive heave compensators with SWL of 700 metric tons and 4,5 meter stroke were connected in parallel. The Cranemaster units was equipped with Cranemaster Adaptive…