Find references by:

Installation of the First Floating Wind Turbines in Provence

Cranemaster supported SBM Offshore with the installation of the company’s first three floating wind turbines in the Provence Grand Large pilot project. Our staff and units, CM3-700T-4500, played a pivotal role in ensuring a safe and efficient installation process located 17 km off the coast of Port-Saint-Louis-Du-Rhône in France.

Mudmat and manifold installation Western Australia with limited rigging height

Mudmat and manifold installation Western Australia with limited rigging height - picture of mudmat being lowered through splash zone

Pile hammering for E.ON at the Rampion project

Customer Challenge: Pile run protection during installation of 116 monopiles at the Rampion Offshore Wind Farm Project off the south coast of England. Cranemaster Solution: Two Cranemaster shock absorbers with SWL of 1000 tons and 700 tons. Protecting the crane and rigging by reducing potential shock loads caused by sudden…

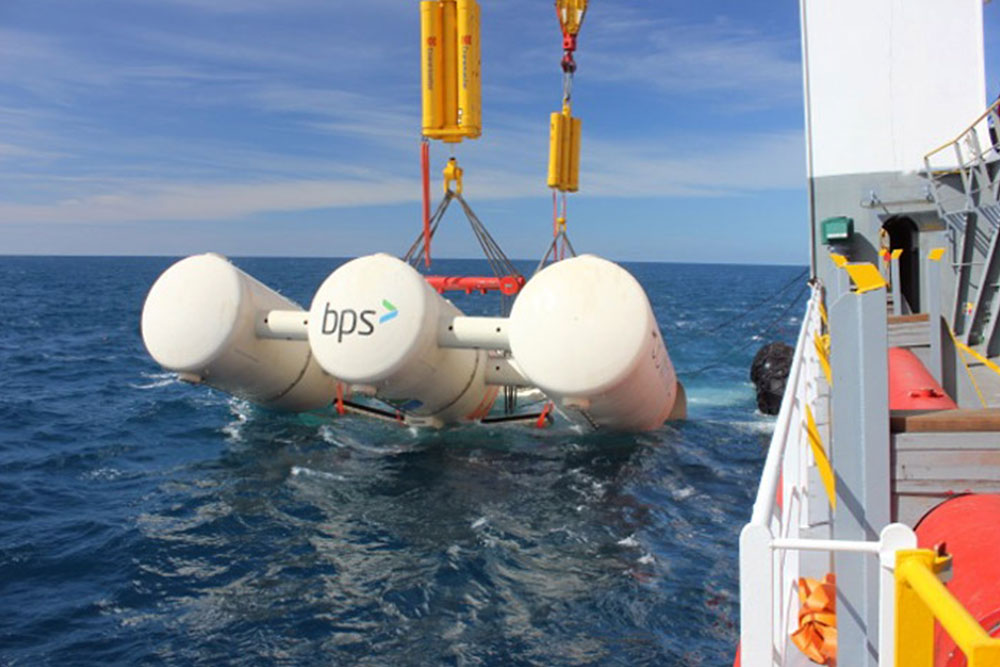

Installation of large wave energy device

Customer Challenge: Installation of the wave energy device bioWAVE near Port Fairy, Victoria, in rough weather conditions. Cranemaster Solution: Two large Cranemaster passive heave compensators with SWL of 700 metric tons and 400 metric tons. The Results: The two Cranemaster units functioned perfectly, resulting in reduced DAF in the splash…

Worlds largest heave compensated lift

Customer Challenge: Enabling installation of large subsea modules of up to 1100 metric tons in higher sea states for the Chevron Gorgon Project. Cranemaster Solution: Two Cranemaster passive heave compensators with SWL of 700 metric tons and 4,5 meter stroke were connected in parallel. The Cranemaster units was equipped with Cranemaster Adaptive…